Services and Capabilites

Sharp Tooling Program

A Sharp Tooling Program establishes an ongoing supply chain solution that improves the use, performance, and procurement efforts for perishable tooling and parts. We collaborate with your procurement, manufacturing, and engineering teams to define an optimal set of parts, processes, and schedules. We maintain an inventory of semi-finished parts for a known, reduced delivery time and consistent quality.

Here's how it works

Our 5-Step Process

- Tooling and Processing Audit (Free)

- Analysis and Service Recommendation

- Collaborative Process Development

- Process Setup and Testing

- Inventory and Program Management

5% Guaranteed Savings

We will not propose a Sharp Tooling Program unless we can deliver you at least 5% savings on your supply chain investment.

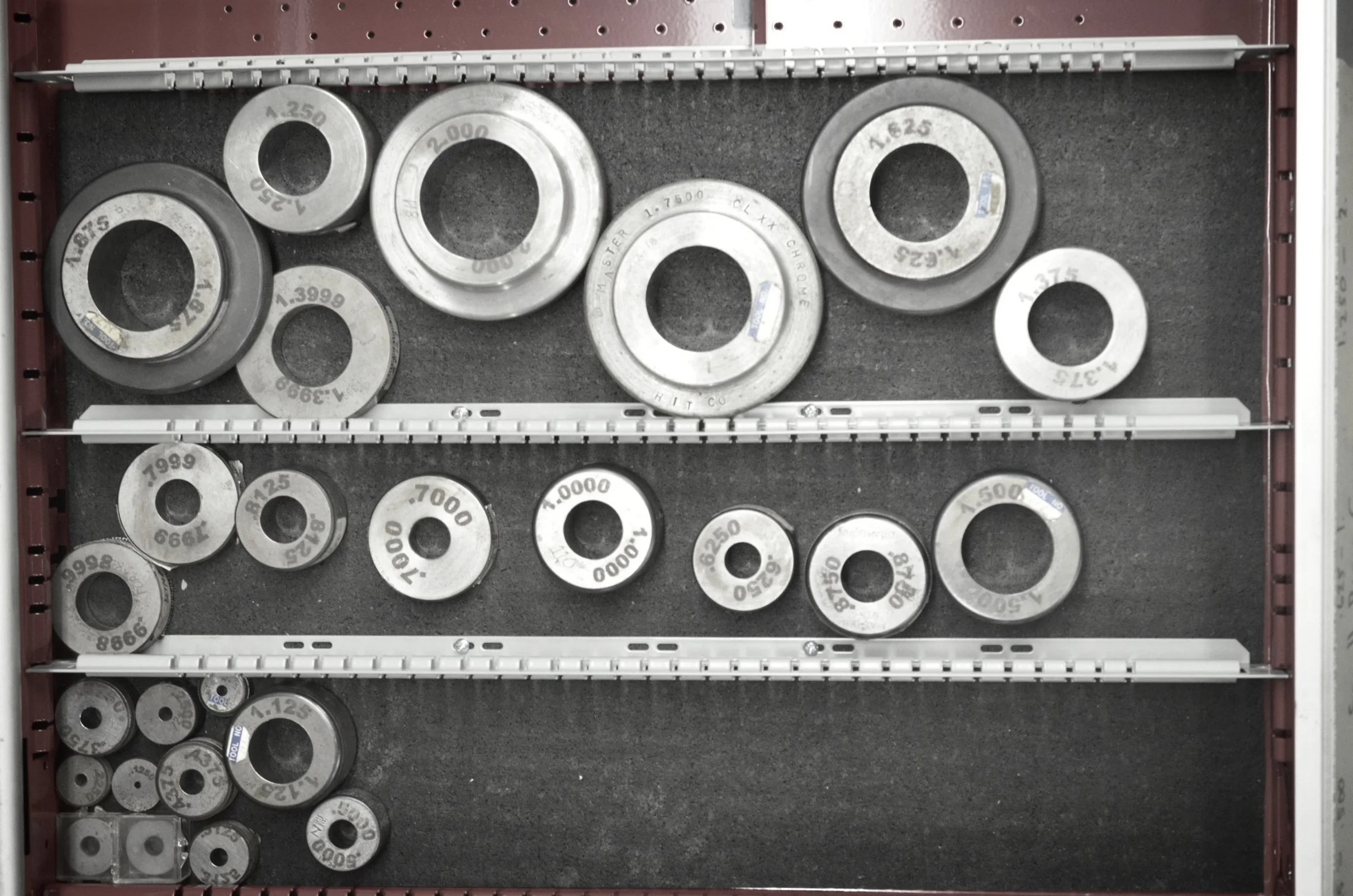

Production Critical Tooling Options

Tooling Program Service

Installation Tools

Punches

Scrapers

Slitters

Blades

Crimp Wheels

Dies

Form Tools

*We are always open to new programs and products*

A Sharp Tooling Program goes beyond machining and into working closely with the customer to develop a customized tooling process. They require tailored prints specific to each product, as well as, a strategic plan to maintain inventory levels for each stage of the tooling process.

- Process Development, Analysis, and Improvement

- Tooling Design and Machining Services

- Reconditioning of Tools

- Poki-yoke: mistake proofing

- 3rd Party Sourcing System

Why Use A Sharp Tooling Program?

- Easy Purchasing

- Set Pricing

- Short Lead Time

- Controlled Inventory Cost

- Reliable Delivery

When a critical tool breaks or dulls, your line is down. Production and procurement team go into crisis mode, throwing daily work into limbo. Costs escalate, processes are interrupted. Tooling programs minimize the impact of these anticipated but unplanned events.